Aplikasi Waste Assessment Model (WAM) Pada Proses Perencanaan Anggaran Menggunakan Sistem SILUNA

Abstract

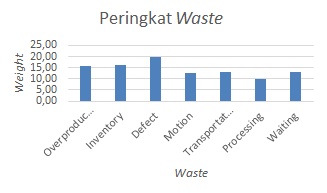

Implementing an audit process is one way to raise the quality of both products and processes. Detecting the presence of waste is one of the audit procedures that can be used. Waste is a behavior in and of itself that adds no value. Lean is the auditing technique used to find waste. Lean primarily focuses on identifying and removing non-value-added activities. Lean has a mechanism for identifying waste in its implementation, and that method is the Waste Assessment Model (WAM). In the Planning Section of the Planning and Finance Bureau of Udayana University, the application of WAM is concentrated on planning to identify waste in the budget process utilizing the SILUNA system. The findings of this study can be summarized as follows: defect is the largest waste with a proportion of 19,79%; inventory are the second sequence of waste with a proportion of 16,35%.

Key Word— Lean; Waste; Waste Assessment Model

Downloads

References

[2] K. Sofa, T. Lathif, M. Suryanto, R. R. Suryono, and J. Timur, “Audit Tata Kelola Teknologi Informasi Menggunakan Kerangka Kerja Cobit 5 Pada Dinas Pekerjaan Umum Kabupaten Tanggamus,” J. Teknol. dan Sist. Inf., vol. 1, no. 1, pp. 39–46, 2020, [Online]. Available: http://jim.teknokrat.ac.id/index.php/sisteminformasi

[3] A. S. Akhilesh N Singh, Lean IT Principles To Practice Toyota Way To Create Value for The Customer & Wealth for IT Organization. NCR Delhi, INdia: Notion Press 2018, 2018.

[4] E. Altayany, “ANALISIS PRIORITAS PERBAIKAN GUNA MEMINIMASI WASTE DOMINAN PADA PROSES PRODUKSI DENGAN FAILURE MODE EFFECT ANALYSIS ANALYTICAL HIERARCHY PROCESS (FMEA AHP) (STUDI KASUS: PT LEZAX NESIA JAYA),” 2018.

[5] A. Naziihah, J. Arifin, and B. Nugraha, “Identifikasi Waste Menggunakan Waste Assessment Model (WAM) di Warehouse Raw Material PT. XYZ,” J. Media Tek. dan Sist. Ind., vol. 6, no. 1, p. 30, 2022, doi: 10.35194/jmtsi.v6i1.1599.

[6] A. R. Putri, L. Herlina, and P. F. Ferdinant, “Identifikasi Waste Menggunakan Waste Assessment Model ( WAM ) Pada Lini Produksi PT . KHI Pipe Industries,” J. Untirta, vol. 5, no. 1, pp. 3–7, 2017, [Online]. Available: http://www.jurnal.untirta.ac.id/index.php/jiss/article/view/1537

[7] R. M. S. Alfajri and Y. Muchtiar, “Penerapan Lean Six Sigma Di Jasa Pelayanan Pengiriman Barang Pt. Dakota Buana Semesta,” J. Fac. Ind. Technol. Bung Hatta Univ., vol. 18, 2021.

[8] A. R. Irwan Setiawan, “Penerapan Lean Manufacturing Untuk Meminimalkan Waste Dengan Menggunakan Metode VSM Dan WAM Pada PT XYZ,” Semin. Nas. Penelit. LPPM UMJ, pp. 1–10, 2021.

[9] I. B. A. E. M. Putra, R. S. Hartati, and Y. Divayana, “Audit Sistem Informasi E-Kinerja Dinas Kependudukan Dan Pencatatan Sipil Kota Denpasar,” Maj. Ilm. Teknol. Elektro, vol. 19, no. 1, p. 107, 2020, doi: 10.24843/mite.2020.v19i01.p16.

[10] R. Patawala and A. D. Manuputty, “Audit Sistem Informasi pada Dinas Perpustakaan dan Kearsipan Kota Salatiga,” Sebatik, vol. 25, pp. 42–49, 2021.

[11] C. D. Oktaviana Soleman, M. Sudarma, and N. Pramaita, “Literature Review Penerapan Teknologi Informasi dan Metode Pengukuran Pada Audit Kepuasan Pelanggan,” Maj. Ilm. Teknol. Elektro, vol. 20, no. 2, p. 289, 2021, doi: 10.24843/mite.2021.v20i02.p13.

[12] R. Wijaya, H. Honni, and H. Pratama, “Audit Sistem Informasi Pada Pt Walepay Finansial Teknologi Menggunakan Kerangka Kerja Cobit 4.1 Dan Balanced Scorecard,” JBASE - J. Bus. Audit Inf. Syst., vol. 3, no. 1, pp. 14–21, 2020, doi: 10.30813/jbase.v3i1.2058.

[13] H. Budiwati, “Pendekatan Lean Six Sigma Dalam Penentuan Prioritas Perbaikan Layanan Bank Berdasarkan Persepsi, Harapan Dan Kepentingan Nasabah,” J. Manaj., vol. 21, no. 1, p. 1, 2017, doi: 10.24912/jm.v21i1.144.

[14] A. Nur Kholis, “Implementasi Lean Service Di Industri Telekomunikasi Guna Meningkatkan Produktivitas (Studi Kasus: PT. Telkom Witel Yogyakarta),” pp. 1–9, 2020.

[15] L. Sihotang, “Peningkatan Service Quality Menggunakan Lean Six Sigma Studi Kasus PT PLN (Persero) Unit Layanan Pelanggan (ULP) Perbaungan,” Tesis, pp. 1–104, 2019.

[16] M. Shodiq and A. Khannan, “Analisis Penerapan Lean Manufacturing untuk Menghilangkan Pemborosan di Lini Produksi PT Adi Satria Abadi Pendahuluan,” J. Rekayasa Sist. Ind., vol. 4, no. 1, pp. 47–54, 2015.

[17] T. Satria, “Perancangan Lean Manufacturing dengan Menggunakan Waste Assessment Model (WAM) dan VALSAT untuk Meminimumkan Waste (Studi Kasus: PT. XYZ),” J. Rekayasa Sist. Ind., vol. 7, no. 1, p. 55, 2018, doi: 10.26593/jrsi.v7i1.2828.55-63.

[18] A. Nur Kholis, “Implementasi Lean Service di Industri Telekomunikasi Guna Meningkatkan Produktivitas (Studi KAsus : PT. Telkom Witel Yogyakarta),” pp. 1–9, 2020.

[19] R. C. Guntoro, T. P. Adhiana, D. T. Industri, F. Teknik, and U. Jenderal, “Identifikasi Waste Menggunakan Metode Waste Assessment Model,” Pros. Semin. Nas. dan Call Pap., vol. 4, no. November, pp. 41–48, 2019.

[20] R. Alfiansyah, Waste Identification With Waste Assessment Model for Implementing Lean Manufacturing To Improve Production Process (Case Study on Glove Production Process). 2018.

[21] Riza Nur Madaniyah, “MINIMASI WASTE DAN LEAD TIME PADA PROSES PRODUKSI LEAF SPRING DENGAN PENDEKATAN LEAN MANUFACTURING,” 2017.

[22] S. Irwan and A. Rahman, “Penerapan Lean Manufacturing Untuk Meminimalkan Waste Dengan Menggunakan Metode VSM Dan WAM Pada PT XYZ,” Semin. Nas. Penelit. LPPM UMJ, pp. 1–10, 2021.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License