Review on Impact of Artificial Intelligent on Efficiency and Productivity in Industrial Automation

Abstract

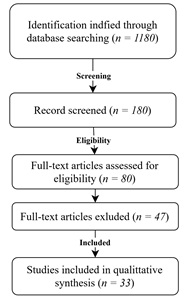

As Industry 4.0 technologies evolve, the application of Artificial Intelligence (AI) in the manufacturing sector has become a major factor in improving operational efficiency, optimizing production processes, and reducing costs, enabling predictive analytics, data-driven maintenance, and automation of tasks that previously required human intervention. This study conducts a systematic literature review (SLR) on various AI methods applied in industrial automation, evaluates the effectiveness of their implementation, and identifies key challenges in their adoption. The Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) and Population,

Intervention, Comparison, Outcome, Context (PICOC) approaches are adopted. The sources used to search the literature included four electronic databases, comprising ScienceDirect, Taylor & Francis, Scopus, and Emerald Insight, resulting in 33 selected articles. The result shows that AI contributes significantly to improving production efficiency, but it still faces challenges in system integration, implementation costs, and workforce readiness. This study provides a comprehensive overview of the effectiveness of AI implementation in industrial automation and the challenges that need to be overcome to optimize competitiveness and production efficiency.

Downloads

References

[2] A. Permana, R. S. Hartati, and I. N. S. Kumara, “Simulasi Penggunaan Komponen Smart Building untuk Meningkatkan IKE di Gedung Rektorat Universitas Udayana,” Majalah Ilmiah Teknologi Elektro, vol. 21, no. 2, p. 237, 2022.

[3] I. A. S. S. Anjani, L. Jasa, and I. R. Agung, “Rancang Bangun Sistem Minimarket Otomatis Berbasis IoT,” Majalah Ilmiah Teknologi Elektro, vol. 19, no. 2, p. 255, 2020.

[4] A. A. A. Sharabati, H. Z. Awawdeh, S. Sabra, H. K. Shehadeh, M. Allahham, and A. Ali, “The role of artificial intelligence on digital supply chain in industrial companies mediating effect of operational efficiency,” Uncertain Supply Chain Manag., vol. 12, no. 3, pp. 1867–1878, 2024.

[5] T. Mandičák, A. Behúnová, and P. Mésároš, “Artificial Intelligence in the Sustainable Design and Manufacturing of Products in Civil Engineering in the Context of Industry 4.0,” Machines, vol. 12, no. 12, 2024.

[6] M. I. Joha, M. M. Rahman, M. S. Nazim, and Y. M. Jang, “A Secure IIoT Environment That Integrates AI-Driven Real-time Short-Term Active and Reactive Load Forecasting with Anomaly Detection: A Real-World Application,” Sensors, vol. 24, no. 23, 2024.

[7] G.-H. Phan, “Integrating long short-term memory for optimal control of 6-DOF welding robot arm,” Adv. Mech. Eng., vol. 16, no. 6, 2024.

[8] R. Rakholia, A. L. Suarez-Cetrulo, M. Singh, and R. S. Carbajo, “AI-Driven Meat Food Drying Time Prediction for Resource Optimization and Production Planning in Smart Manufacturing,” IEEE Access, vol. 13, pp. 22420–22428, 2025.

[9] T. Basmaji et al., “AI-powered health monitoring of anode baking furnace pits in aluminum production using autonomous drones,” Eng. Appl. Artif. Intell., vol. 122, 2023.

[10] P. Skudlik and A. Wróbel, “Analysis of the efficiency of pneumatic actuator regulation in selected production processes using artificial intelligence, graph algorithms, and probabilistic methods, taking into account failure rates and return on investment costs,” in Materials Research Proceedings, 2024, vol. 46, pp. 338–345.

[11] N. Iqbal et al., “Enhanced time-constraint aware tasks scheduling mechanism based on predictive optimization for efficient load balancing in smart manufacturing,” J. Manuf. Syst., vol. 64, pp. 19–39, 2022.

[12] M. Sanchez, E. Exposito, and J. Aguilar, “Autonomic computing in manufacturing process coordination in industry 4.0 context,” J. Ind. Inf. Integr., vol. 19, 2020.

[13] A. B. Moniz, M. Candeias, and N. Boavida, “Changes in productivity and labour relations: artificial intelligence in the automotive sector in Portugal,” Int. J. Automot. Technol. Manag., vol. 22, no. 2, pp. 222–244, 2022.

[14] J. Liu, X. Jiang, M. Shi, and Y. Yang, “Impact of Artificial Intelligence on Manufacturing Industry Global Value Chain Position,” Sustain., vol. 16, no. 3, 2024.

[15] D. Cardoso and L. Ferreira, “Application of predictive maintenance concepts using artificial intelligence tools,” Appl. Sci., vol. 11, no. 1, pp. 1–18, 2021.

[16] A. Przybyś-Małaczek, I. Antoniuk, K. Szymanowski, M. Kruk, and J. Kurek, “Application of Machine Learning Algorithms for Tool Condition Monitoring in Milling Chipboard Process,” Sensors, vol. 23, no. 13, 2023.

[17] J. Fuentes, J. Aguilar, E. Montoya, and Á. Pinto, “Autonomous Cycles of Data Analysis Tasks for the Automation of the Production Chain of MSMEs for the Agroindustrial Sector,” Inf., vol. 15, no. 2, 2024.

[18] J. M. Rožanec et al., “Human-centric artificial intelligence architecture for industry 5.0 applications,” Int. J. Prod. Res., 2022.

[19] A. Manimuthu, V. G. Venkatesh, Y. Shi, V. R. Sreedharan, and S. C. L. Koh, “Design and development of automobile assembly model using federated artificial intelligence with smart contract,” Int. J. Prod. Res., vol. 60, no. 1, pp. 111–135, 2022.

[20] P. Zajec et al., “Few-shot learning for defect detection in manufacturing,” Int. J. Prod. Res., vol. 62, no. 19, pp. 6979–6998, 2024.

[21] D. Bratić, P. Miljković, D. Jurečić, and T. Grabarić, “AI-Driven Random Forest Model and the Six Sigma Approach for Enhancing Offset Printing Process and Product Quality,” Appl. Sci., vol. 15, no. 5, 2025.

[22] A. C. Silva, J. Machado, and P. Sampaio, “Predictive quality model for customer defects,” TQM J., vol. 36, no. 9, pp. 155–174, 2024.

[23] A. Taherizadeh and C. Beaudry, “An emergent grounded theory of AI-driven digital transformation: Canadian SMEs’ perspectives,” Ind. Innov., vol. 30, no. 9, pp. 1244–1273, 2023.

[24] M. Verdugo-Cedeño, S. Jaiswal, V. Ojanen, L. Hannola, and A. Mikkola, “Simulation-Based Digital Twins Enabling Smart Services for Machine Operations: An Industry 5.0 Approach,” Int. J. Hum. Comput. Interact., vol. 40, no. 20, pp. 6327–6343, 2023.

[25] R. Fornasiero, L. Kiebler, M. Falsafi, and S. Sardesai, “Proposing a maturity model for assessing Artificial Intelligence and Big data in the process industry,” Int. J. Prod. Res., 2024.

[26] D. Y. A. Santillan, L. A. N. Sandoval, A. I. M. Santillán, P. J. A. Yataco, H. S. P. Quispe, and N. R. H. Huapaya, “Industrial process optimization through advanced HMI systems: exploring the integration of IoT and AI,” Indones. J. Electr. Eng. Comput. Sci., vol. 36, no. 2, pp. 817–825, 2024.

[27] G. Szabó and J. Pető, “Intelligent wireless resource management in industrial camera systems: Reinforcement Learning-based AI-extension for efficient network utilization,” Comput. Commun., vol. 216, pp. 68–85, 2024.

[28] I. Jackson, D. Ivanov, A. Dolgui, and J. Nambar, “Generative artificial intelligence in supply chain and operations management: a capability-based framework for analysis and implementation,” Int. J. Prod. Res., vol. 62, no. 17, pp. 6120–6145, 2024.

[29] K. Demeter, L. Szász, B. G. Rácz, and L. Z. Györfy, “Fourth industrial (r)evolution? Investigating the use of technology bundles and performance implications,” J. Manuf. Technol. Manag., vol. 35, no. 9, pp. 1–23, 2024.

[30] T. A. Grigorievich, “The implementation of lean and digital management techniques using artificial intelligence in industrial settings,” Discov. Artif. Intell., vol. 4, no. 1, 2024.

[31] J. Dele Owolabi, D. Malagwi, O. Oyeyipo, E. O. Ola-Ade, and P. F. Tunji-Olayeni, “Application of artificial intelligence in the Nigerian building and construction industry,” Int. J. Adv. Appl. Sci., vol. 9, no. 10, pp. 33–39, 2022.

[32] A. De Carolis et al., “The Digital REadiness Assessment MaturitY (DREAMY) framework to guide manufacturing companies towards a digitalisation roadmap,” 2025.

[33] D. Sjödin, V. Parida, and M. Kohtamäki, “ Artificial intelligence enabling circular business model innovation in digital servitization: Conceptualizing dynamic capabilities, AI capacities, business models and effects,” Technol. Forecast. Soc. Change, vol. 197, no. October, 2023.

[34] G. L. Tortorella, D. Powell, P. Hines, A. Mac Cawley Vergara, D. Tlapa-Mendoza, and R. Vassolo, “ How does artificial intelligence impact employees’ engagement in lean organisations?,” Int. J. Prod. Res., vol. 63, no. 3, pp. 1011–1027, 2025.

[35] M. Peruzzini, E. Prati, and M. Pellicciari, “A framework to design smart manufacturing systems for Industry 5.0 based on the human-automation symbiosis,” Int. J. Comput. Integr. Manuf., vol. 37, no. 10–11, pp. 1426–1443, 2024.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License