Sistem Proteksi Thermal Overload Relay (TOR) pada Motor Induksi 3 Phasa sebagai Penghancur Batu Bara di PT. Mitrabara Adiperdana Tbk

Abstract

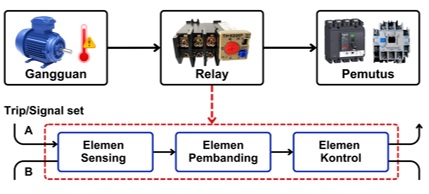

During operation, the induction motor used as a coal crusher may experience excessive workload, leading to potential overheating and system trips that disrupt the production process. To mitigate such issues, a reliable system is required to limit or prevent operational disturbances. This research collected data on the induction motor protection system at PT Mitrabara Adiperdana Tbk, followed by calculations of relay settings, specifically Over Current (OC) settings, which were then compared with observed field data. The findings indicate a significant discrepancy between the Time Overcurrent Relay (TOR) settings observed in the field and the calculated TOR settings based on motor current performance data from January and February 2023. This discrepancy arises from the operational shift of the crusher motor, which initially functioned as the primary crusher and later served as a backup. As a primary crusher, the motor operated at higher power and current levels, reaching 35 A. However, after transitioning to a backup role, the motor's performance declined, with the current reducing to 9.9 A. Similarly, power output varied monthly, with the highest recorded in January at 9.91 kW, decreasing to 9.05 kW in February. These changes in motor performance, particularly reduced current and power, significantly influenced the calculated TOR settings.

Downloads

References

[2] Yasmin, S. Y., & Permata, E. (2022). SISTEM PROTEKSI SWITCH GEAR 5P1_1S1_U5 UNTUK MOTOR CEMENT MILL DI PT CEMINDO GEMILANG PLANT BAYAH. Jurnal Universal Technic, 1(1), 118-127.

[3] Inayati, W., Nurhadi, N., & Effendy, M. (2021). Identifikasi Kerusakan Outer Race Bearing Motor Pada Hoist Crane Menggunakan Metode Short Time Fourier Transform. Journal of Mechatronic and Electrical Engineering, 1(1), 8-18.

[4] S Syukur, A dan Adrianto, S. “Studi Sistem Proteksi Motor Induksi Pada Motor di Pabrik PT.Semen Bosowa Maros”, Skripsi, Unoversitas Muhammadiyah Makassar, Makassar, 2022.

[5] Puspita, T., & Darmawan, I. A. (2023). Thermal Overload Relay (TOR) Sebagai Sistem Proteksi Motor Induksi 3 Fasa Pada Mesin Molding Biofuel Pelletizer Di PT. Sejin Lestari Furniture. Jurnal Teknik Mesin, Industri, Elektro dan Informatika, 2(2), 168-181.

[6] Shaikh, S., Kumar, D., Hakeem, A., & Soomar, A. M. (2022). Protection system design of induction motor for industries. Modelling and Simulation in Engineering, 2022(1), 7423018.

[7] Zagirnyak, M., Kalinov, A., & Melnykov, V. (2019). Decrease of the thermal overloads of a variable-frequency electric drive at damages in the electric circuit of an induction motor stator. Przeglad Elektrotechniczny, 95(5), 43-46.

[8] Pujiyanto, F., & Darmana, E. (2022). Analisis Perubahan Temperatur Induksi Motor 3 Phase Berbasis Fuzzy Inference System (FIS). JURNAL SAINS DAN TEKNOLOGI MARITIM, 23(1), 15-30.

[9] Surya, D. Sistem Proteksi pada Motor Induksi 3 Phase 200 KW Sebagai Penggerak Pompa Hydran (electric fire pump). Jurnal Fakultas Teknik Universitas Palembang, 2015.

[10] Muzzammel, R., Akram, M. N., Asghar, S., Saleem, A., & Muqeem, U. (2018). Simulation Analysis of Fully Protected Induction Motor. International Journal of Scientific & Engineering Research, 9(10), 770-775.

[11] Ari Wicaksono, “Thermal Overload Relay (TOR/TOL)”, 2014.

[12] Sartika, L. (2023). ANALISA PENGARUH PERUBAHAN BEBAN TERHADAP KINERJA MOTOR INDUKSI 3 FASA SCRAPER CONVEYORDI PT. CITRA SIWIT LESTARI. Jurnal Elektro dan Telekomunikasi Terapan (e-Journal), 10(1), 7-16.

[13] Abdo, A., Siam, J., Abdou, A., Shehadeh, H., & Mustafa, R. (2024). Practical Test on the Operation of the Three-Phase Induction Motor under Single-Phasing Fault. Applied Sciences, 14(11), 4690.

[14] Triyanto, A., Indrakoesoema, K., & Kusnadi, H. (2023). Proteksi Sistem Tenaga.

[15] Prasetia, A. M., Sartika, L., Sanjaya, D., & Samanta, R. (2024). Implementation of Variable Speed Drive as Starting Control of Three Phase Induction Motor. Jurnal Edukasi Elektro, 8(2).

[16] Choudhury, S. (2021). Dynamic Testing of GE Multilin 869 Motor Protection Relay for Stator Inter-turn Faults.

[17] Prasetia, A. M., Sartika, L., & Nur, M. (2024). MENGATUR KECEPATAN MOTOR INDUKSI 3 FASA MENGGUNAKAN SLIDING MODE CONTROL (SMC) DENGAN FIELD ORIENTED CONTROL (FOC). Elektrika Borneo, 10(2), 58-63.

[18] Sartika, L., & Prasetia, A. M. (2021). PERBANDINGAN FUZZY LOGIC CONTROL DAN ADAPTIVE NEURO FUZZY INFERENCE SYSTEM PADA PENGATURAN KECEPATAN MOTOR INDUKSI TIGA FASA. Jurnal Borneo Saintek, 4(2), 100-108.

[19] Sartika, L., Prasetia, A. M., & Sudirman, F. R. (2024). Kontrol tegangan pada terminal generator menggunakan AVR berbasis neural network. JURNAL ELTEK, 22(1), 29-37.

[20] Norhan, M. “Analisa Pengaruh Beban Terhadap Kinerja Motor Induksi 3 Fasa (Chain Feeder) di PT. Pesona Khatulistiwa Nusantara”, Skripsi, Universitas Borneo Tarakan, 2021.

[21] Praharto, dan Fitrizawati. “Analisa Thermal Overload Relay (TOR) Type Lrd08c Pada Sistem Proteksi 3 Fasa Belt Conveyor 37 KW”, Jurnal Sekolah Tinggi Wiworotomo, Vol. 12, No. 1, 2020.

[22] Edi, M. J. “Evaluasi Listrik dan sistem proteksi dan setting rating arus terhadap penggunaan motor-motor listrik dan pompa air pada circulating water dan boiler feed di PT. Vale Sorowako”, Skripsi, Universitas Muhammadiyah Makassarm Makassar, 2010.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License