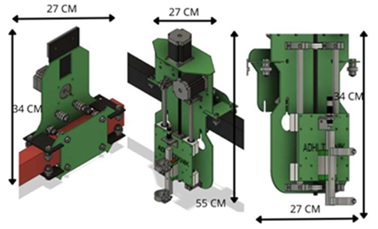

Design And Construction Of A 3-Axis Computer Numerical Control Plasma Arc Cutting Machine With Mach3 Controller

Abstract

This study investigates the design of a CNC machine with a MACH 3 controller and a floating Z-axis to enhance efficiency and precision in the cutting process of iron plates, particularly for the production of laundry machine bodies at Adhi Teknik, a small and medium-sized enterprise (SME) in Bali. The research methodology includes observations and experiments conducted at the Adhi Teknik Workshop and the Laboratory of the Electrical Engineering Study Program. The test results show that the designed CNC machine is able to work optimally with high movement accuracy with an error value of 0.00315% to 0.0125%. The use of electrical energy of CNC machines tested on 304 stainless plate workpieces with a thickness of 1 mm has an average of 104 to 718 Wh on plasma and compressor control systems. The cutting error for basic patterns ranges from 0% to 0.266%, and for additional patterns, it ranges from 0.66% to 0.518%. Based on the research results, the designed CNC machine successfully improves cutting efficiency and precision. Further development could include the creation of a knockdown frame, the use of hard gears, an inverter blowback system, and the addition of a water tank.

Downloads

References

[2] I. Permatasari, “Rancang Bangun Mesin Computer Numerical Control (CNC) Laser Cutter 3 Axis Menggunakan Breakout Board USB MACH3 dan Motor Stepper NEMA 23,” Universitas Lampung, Bandar Lampung, 2024.

[3] Anrinal, I. M. Putra, and R. O. Viola, “Desain Sistem Manufaktur Mesin CNC Laser Engraver,” Jurnal Teknik Mesin Institut Teknologi Padang, vol. 12, no. 1, pp. 32–38, Apr. 2022, doi: 10.21063/jtm.2022.v12.i1.32-38.

[4] Suparno, Suwarto, Z. Arifin, and Susanna, “RANCANG BANGUN MESIN CNC PLASMA CUTTING 3 AXIS,” Jurnal Sains Terapan Teknologi Informasi), vol. 14, no. 2, pp. 36–41, Jul. 2022, doi: 10.46964/justti.v14i2.1549.

[5] A. B. Hendrawan and N. A. Ariyanto, “Rancang Bangun Mesin CNC Router 3 Axis Berbantu Perangkat Lunak Autodesk Inventor 2015,” Journal Mechanical Engineering, vol. 9, no. 2, pp. 31–37, 2020.

[6] X. Liu dan D. Chang, "An Improved Method for Optimizing CNC Laser Cutting Paths for Ship Hull Components with Thicknesses up to 24mm", Journal of Marine Science and Engineering, 11(3), p.652., https://doi.org/10.3390/jmse11030652, (2023)

[7] F. N. Saputro and W. Sumbodo, “Pengaruh Ketinggian Torch Terhadap Lebar KERF dan Kekasaran Permukaan pada Pemotongan CNC Plasma ARC Cutting dengan Bahan Baja ST37,” Jurnal Kompetensi Teknik , vol. 11, no. 2, pp. 22–27, 2019.

[8] A. Z. Rahman, T. S. Prabowo, and P. M. Santika, “Desain dan Manufaktur Mesin CNC Plasma 3 Sumbu PT. Bangun Mesin Sejahtera,” Jurnal Teknik Mesin, vol. 3, no. 1, pp. 1–6, Feb. 2019.

[9] Roswaldi, Julsam, Kartika, A. Fendri, and Mulyadi, “Implementasi Mini CNC Router 3 Axis untuk Pembuatan Huruf dan Gambar Berbasis GRBL 3.6.1,” Proceeding Seminar Nasional Politeknik Negeri Lhokseumawe , vol. 3, no. 1, pp. 95–102, Oct. 2019.

[10] H. Harja, H. Setiawan, D. Muslim, A. Priyamanggala, and R. Kurniawan, “Preliminary Development of Concrete 3D Printing Machine Controller Based on Mach3 Control Board,” in Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science, INSTICC, Dec. 2023, pp. 931–936. doi: 10.5220/0011958800003575.

[11] Mahmood Ali and Haider Mohsin, "Design and Fabrication of 3 Axes Mini CNC Milling Machine", IOP Conf. Ser.: Mater. Sci. Eng. 1094 012005, (2021)

[12] A. Anrinal, M. A. Zamhari, and A. Yanto, “Pengaruh Setting Firmware terhadap Hasil Engraving pada Mesin CNC Laser Engraver,” Jurnal Teknik Mesin Institut Teknologi Padang, vol. 14, no. 1, pp. 21–26, Apr. 2024, doi: 10.21063/jtm.2024.v14.i1.21-26.

[13] D. U. Suwarno, “Using a Stepper Motor as a Low-Power, Low-rotation DC Generator For Renewable Energy Harvesting,” in E3S Web of Conferences, EDP Sciences, Jan. 2024, pp. 1–5. doi: 10.1051/e3sconf/202447503004.

[14] B. C. Wibowo and F. Nugraha, “Stepper Motor Speed Control Using Start-Stop Method Based on PLC,” Jurnal Teknik Elektro dan Komputer, vol. 10, no. 3, pp. 213–220, Dec. 2021, Accessed: Aug. 27, 2024. [Online]. Available: https://ejournal.unsrat.ac.id/index.php/elekdankom

[15] Syafii, S. A. Putri, and Y. Mayura, “Improve Continuity Supply Of PV System Using Arduino-Based Transfer Switch,” INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH, vol. 9, no. 2, pp. 768–772, 2020, [Online]. Available: www.ijstr.org

[16] A. Rakhim, “ANALISIS PENGGUNAAN EMI FILTER 220 VAC/40A SEBAGAI PENYARING DERAU TEGANGAN PADA PERANGKAT DAC-SIK REAKTOR TRIGA 2000 BANDUNG,” 2021.

[17] I. Rasyidin dan Hamdani, "Design and Build Microcontroller-Based Computer Numerical Control (CNC) Machine", Journal of Information Technology, Computer Science and Electrical Engineering, 1(3), 24–35. https://doi.org/10.61306/jitcse.v1i3.73 , (2024)

[18] T. Vishnu Vardhan dan B. Sridhar Babu, "Chapter nine - Multiaxis CNC Programming and machining", Modern Manufacturing Processes by Woodhead Publishing, Pages 167-175,ISBN 9780128194966, https://doi.org/10.1016/B978-0-12-819496-6.00009-9., (2020)

[19] E. Rui, "Design and Application of a Desktop CNC Lathe Control System", 6GN for Future Wireless Networks, Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering, vol 439., https://doi.org/10.1007/978-3-031-04245-4_15, (2021)

[20] Z. H. Khan et al., "Development of a Low-Cost CNC Machine Laser Engraver," IEEE 12th Annual Ubiquitous Computing, Electronics & Mobile Communication Conference (UEMCON),pp. 0376-0382, doi: 10.1109/UEMCON53757.2021.9666661., (2021)

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License